Clutch

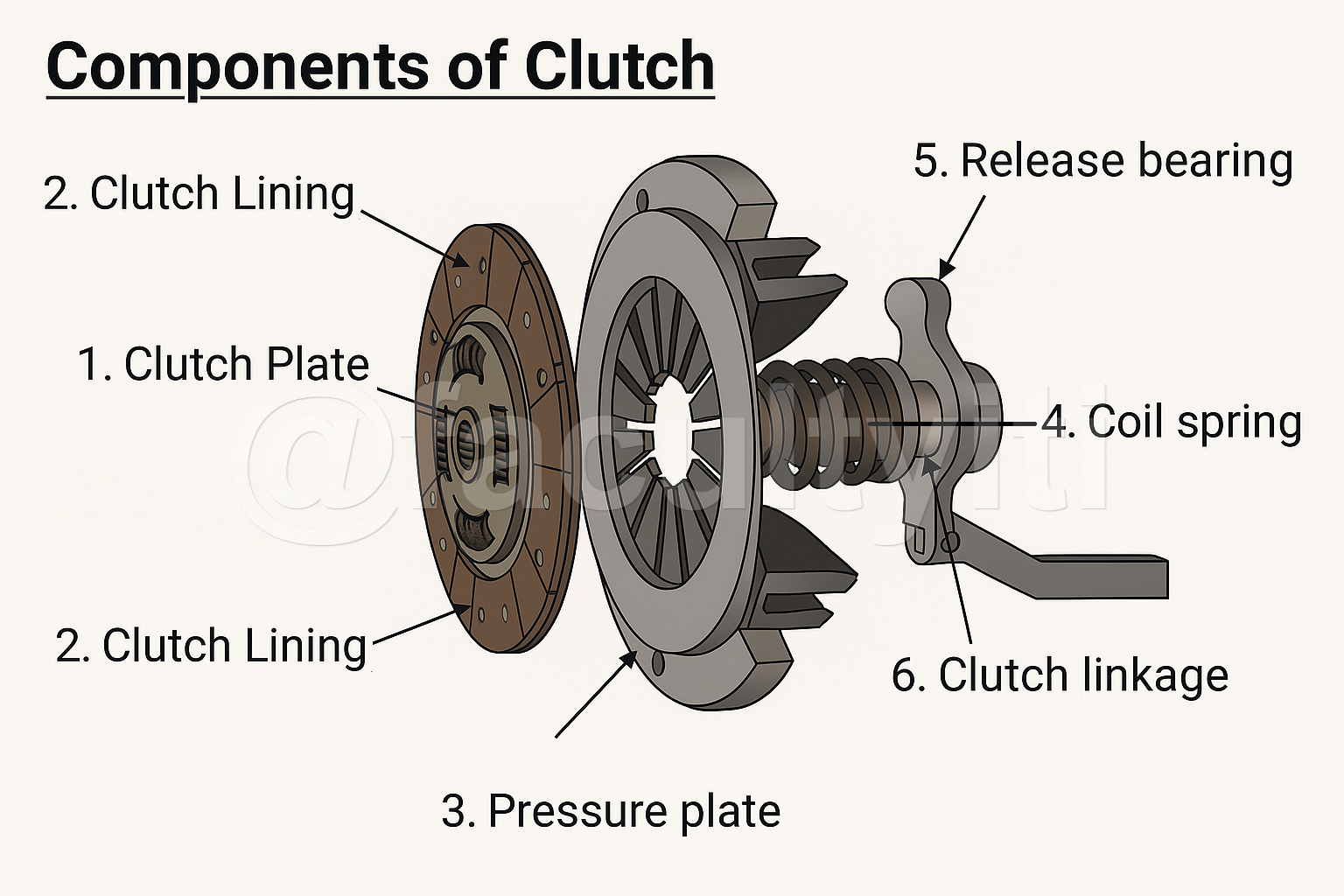

Types of Clutch Linings:

1. Solid Woven Lining types

2. Moulded Lining types

Solid Woven lining type In this type, Clothes are stitched with the suitable thickness.

Moulded lining types It is formed with the help of asbestos, fibre, glass particles, cloth, metal powder and sticking component with particular pressure.

Clutch

Ball Bearing vs Plain Bearing in Release Bearings

1. Ball Bearing

Used In: Heavy-duty vehicles (trucks, buses, tractors)

Why It's Chosen:

a. Handles higher axial loads and rotational speeds

b. Offers low friction and smooth operation under stress

Ideal for frequent clutch use and longer duty cycles

2. Plain Bearing

Used In: Light vehicles (cars, motorcycles)

Why It's Chosen:

a. Simpler design and lower cost

b. Suitable for moderate loads and less frequent clutch engagement

c. Easier to manufacture and maintain in compact systems

Clutch

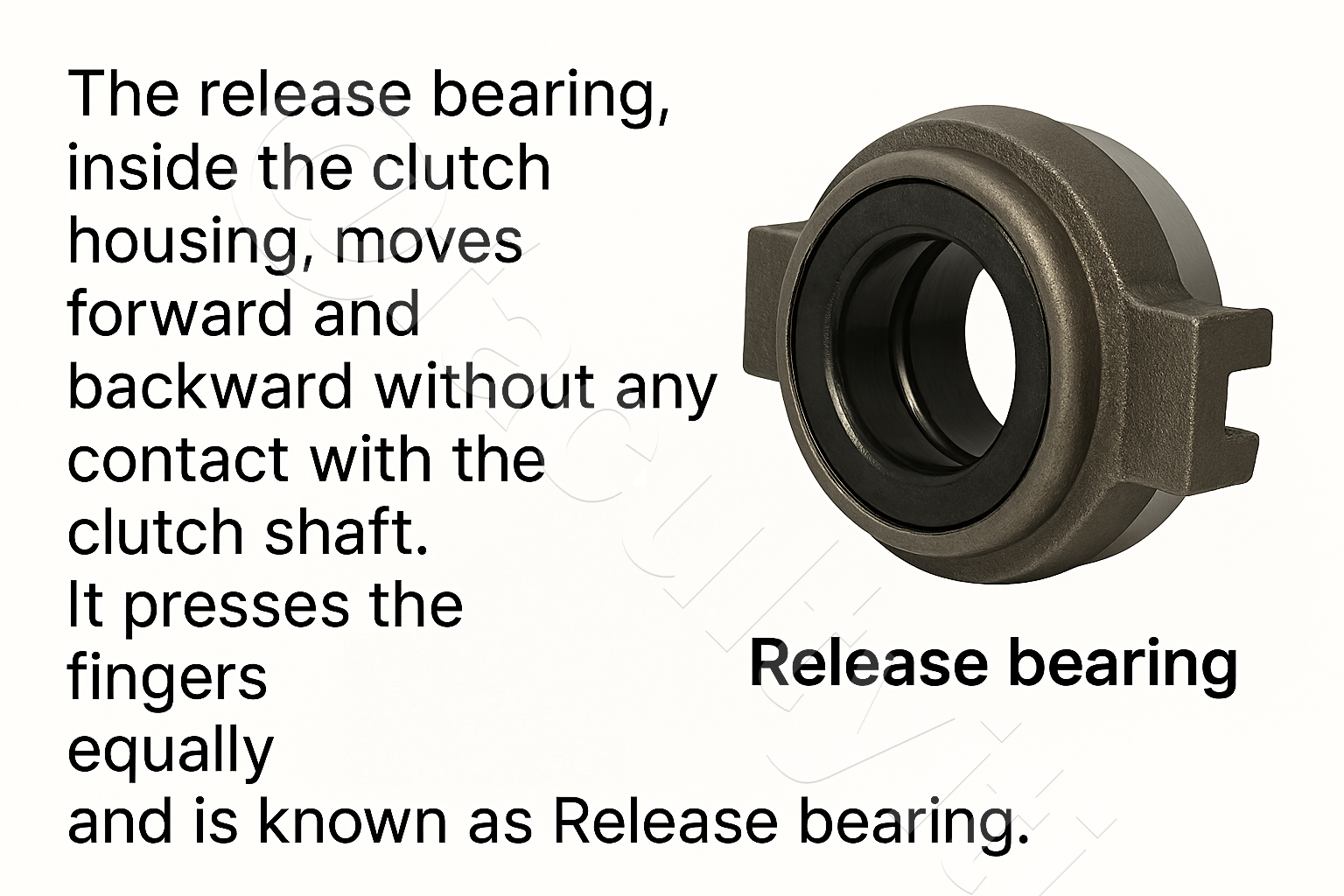

Located inside the clutch housing, the release bearing moves forward and backward without contacting the clutch shaft. It evenly presses the clutch fingers during operation, enabling smooth engagement and disengagement of the clutch.

Clutch

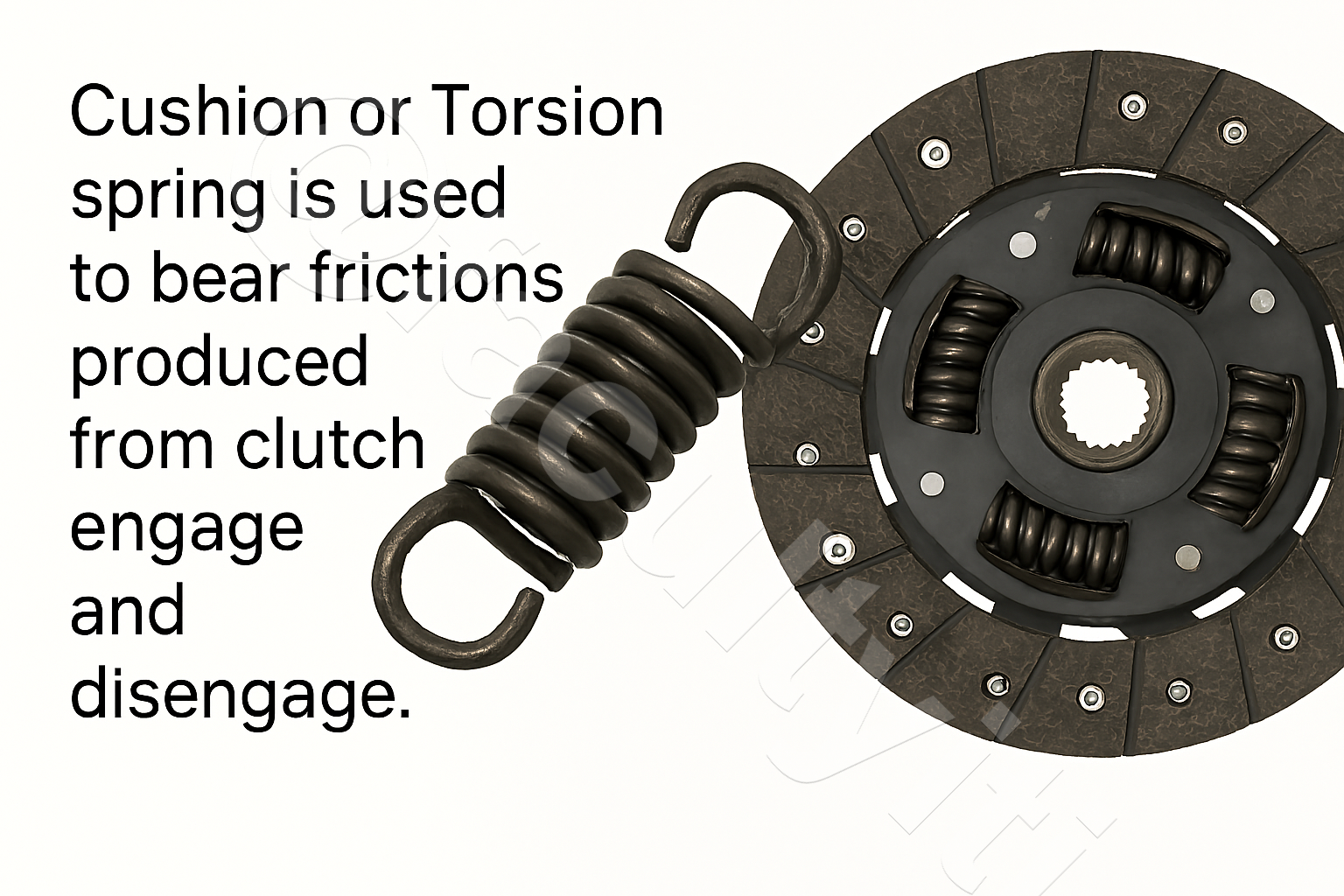

Cushion or torsion springs are used in clutch systems to absorb the friction and vibrations generated during clutch engagement and disengagement. They help smooth out the torque transfer and reduce wear on clutch components, enhancing durability and driving comfort.

Clutch

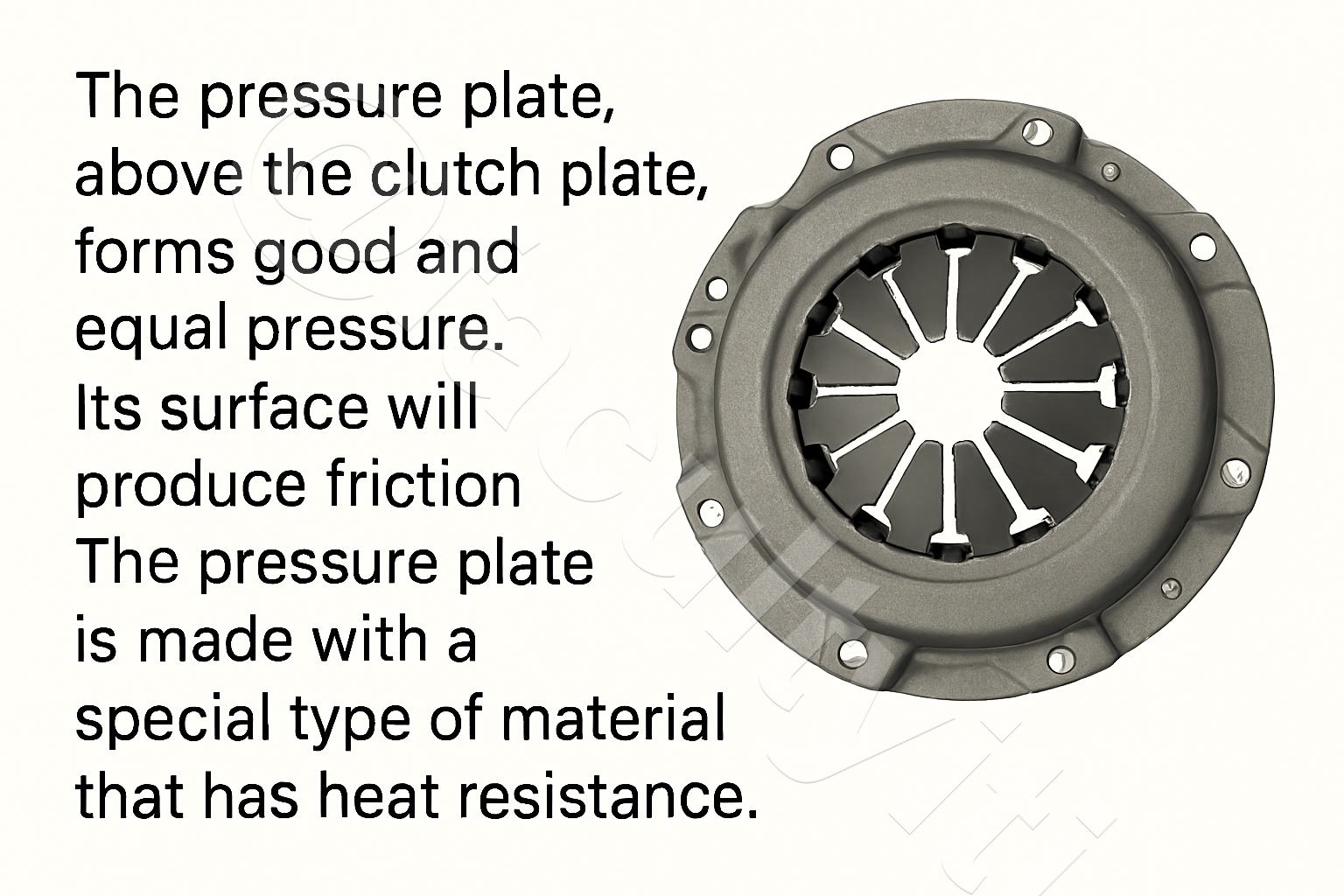

The pressure plate sits above the clutch plate to apply uniform pressure. Its surface is precision-machined to ensure consistent friction. Made from heat-resistant materials, it maintains performance under high temperatures. A diaphragm spring is integrated to regulate clamping force efficiently.

Clutch

Two Common Clutch Actuation Mechanisms

1. Direct Contact with Diaphragm Fingers

Design: The release bearing directly presses against the tips of the diaphragm spring fingers.

Function: When the clutch pedal is pressed, the bearing moves forward and pushes the diaphragm fingers inward.

Effect: This action causes the diaphragm spring to pivot at its fulcrum, pulling the pressure plate away from the clutch disc and disengaging the clutch.

Common Use: Found in many modern vehicles with diaphragm spring clutches due to simplicity and compactness.

2. Indirect Actuation via Fulcrum, Lever, Collar, and Helical Spring

Design: The release bearing doesn’t touch the diaphragm directly. Instead, it moves a lever or collar that then acts on the diaphragm spring.

Function: The bearing pushes a fulcrum lever, which transfers force to a collar or helical spring that compresses the diaphragm spring.

Effect: This setup allows for more mechanical advantage or smoother operation in certain heavy-duty or older clutch systems.

Common Use: Seen in lever-type clutches, especially in trucks, tractors, or industrial machinery.

Templates and Gauges

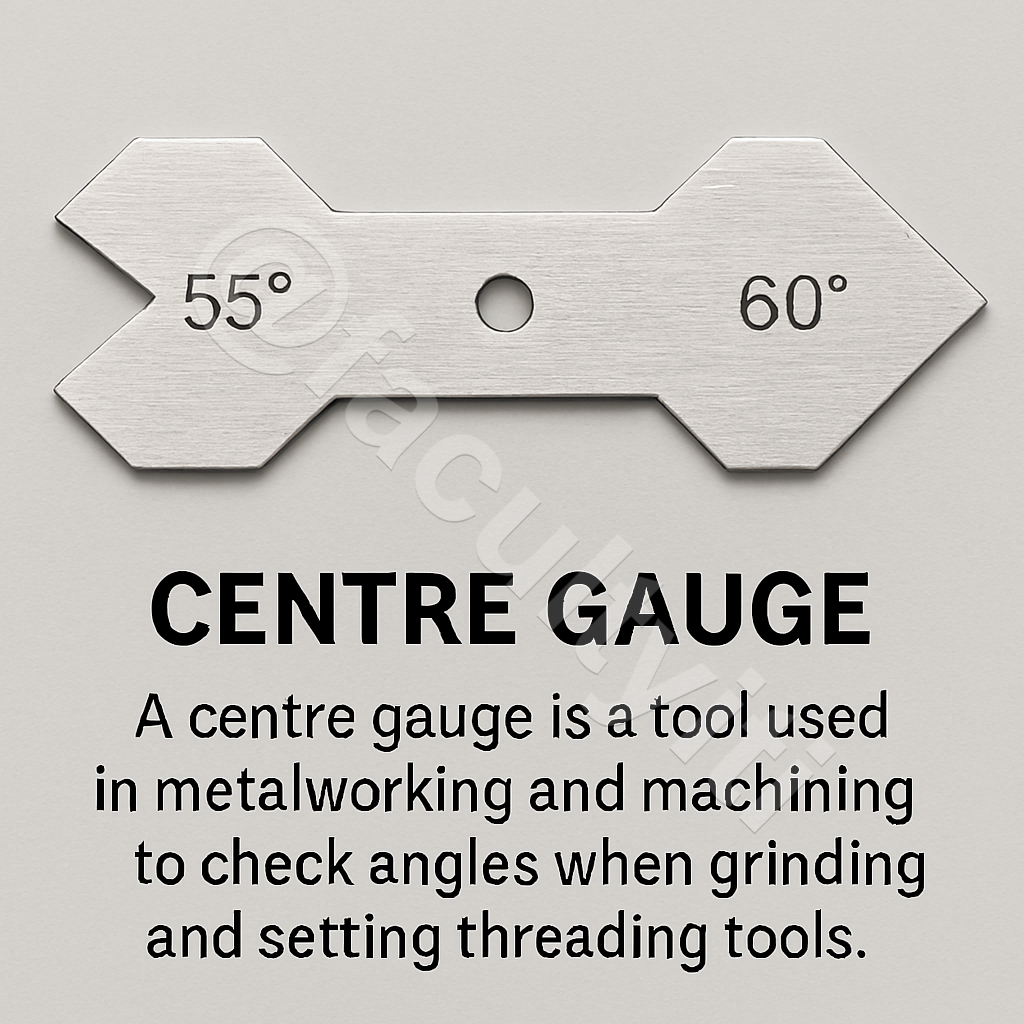

A Centre Gauge (also known as a Fishtail Gauge) is a precision measuring tool used primarily in metalworking and machining, especially on a lathe. It helps ensure accurate angles when grinding and setting threading tools.

Templates and Gauges

A Small Hole Gauge is a precision tool used to measure the internal diameter of small holes, typically ranging from 1/8 inch to 1/2 inch (3mm to 13mm). It’s ideal for tight spaces like valve guides, slots, and recesses.

Templates and Gauges

A feeler gauge is a set of thin metal blades or wires of varying thicknesses, each marked with its measurement. These blades are used to check the spacing between components especially where conventional measuring tools like calipers can't reach.

Templates and Gauges

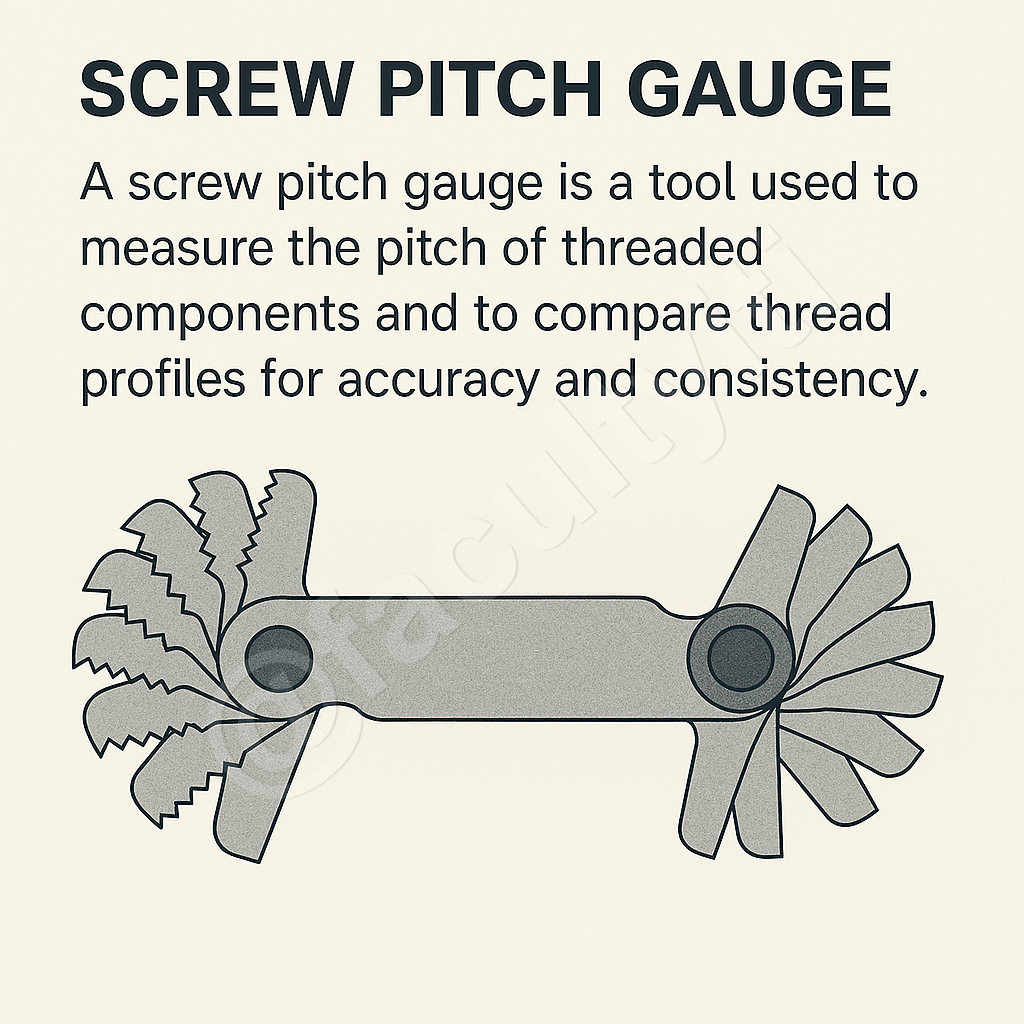

A screw pitch gauge is a tool used to measure the pitch of threaded components and to compare thread profiles for accuracy and consistency.

Templates and Gauges

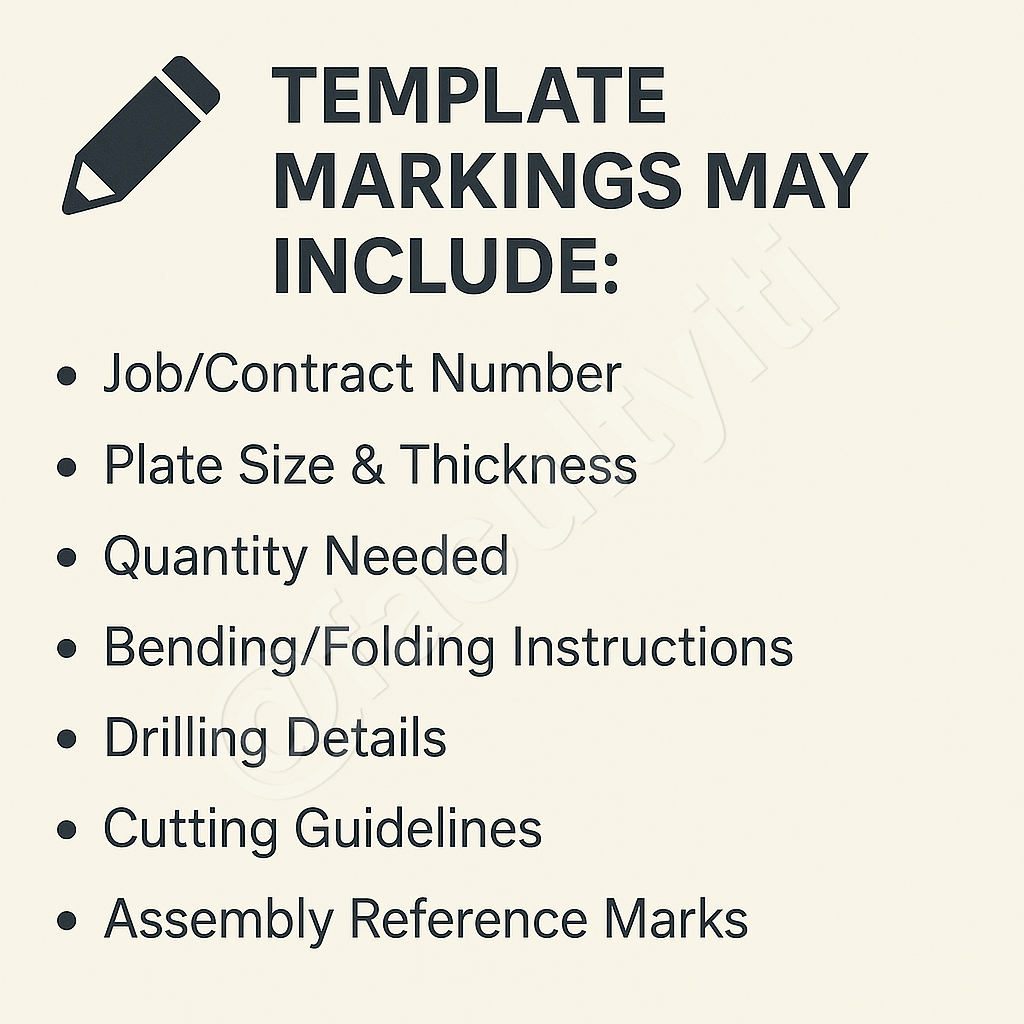

📝 Template Markings May Include:

Job/Contract Number

Plate Size & Thickness

Quantity Needed

Bending/Folding Instructions

Drilling Details

Cutting Guidelines

Assembly Reference Marks

Templates and Gauges

🔧 Benefits of Templates are:

Saves Time: Eliminates repeated measuring and marking for identical parts.

Reduces Waste: Helps optimize material layout and usage.

Improves Accuracy: Guides cutting and shaping processes.

Quick Checks: Easily verifies bend angles and contours.

Templates and Gauges

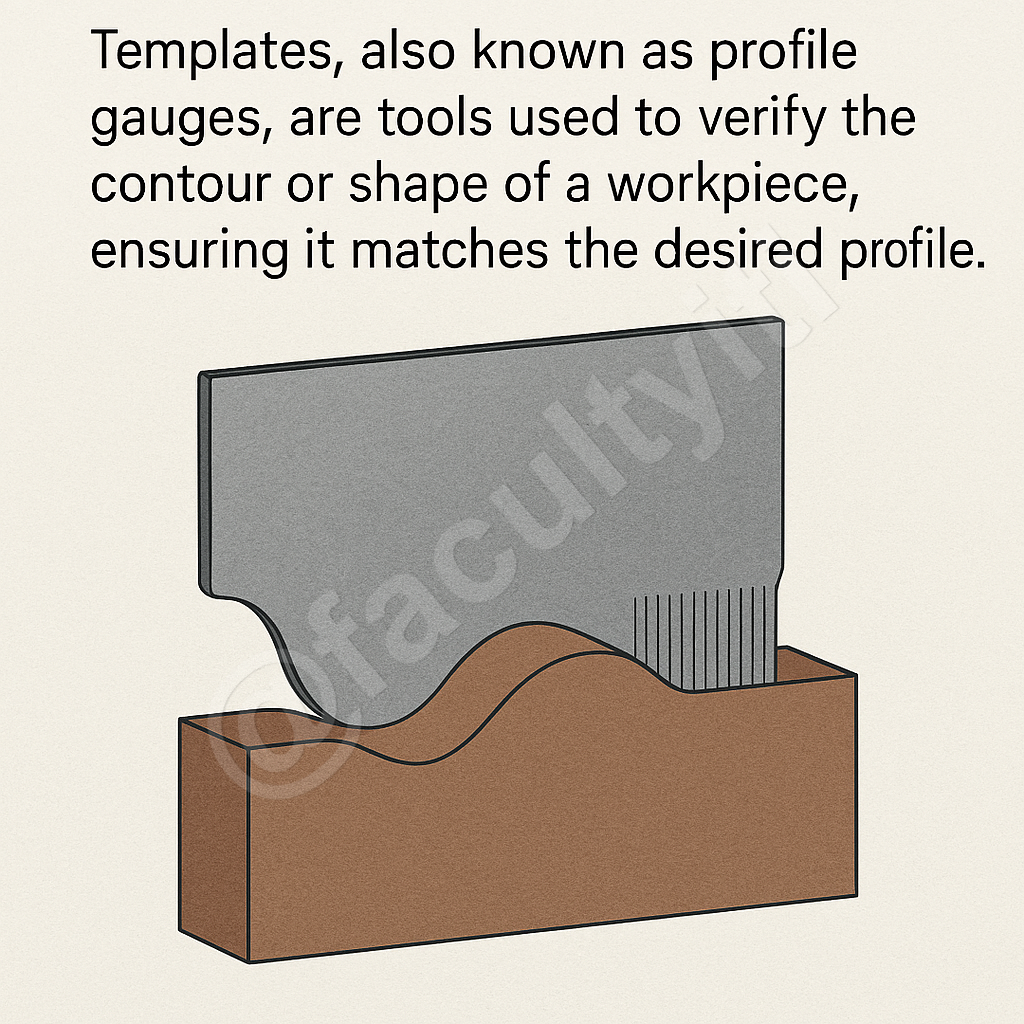

Templates, also known as profile gauges, are tools used to verify the contour or shape of a workpiece, ensuring it matches the desired profile. They are typically made from steel sheets and serve as reference patterns for checking form accuracy.

Safety

Some Emergency Signs for Workshop Safety and First Aid

Safety

Some Prohibition Signs for Workshop Safety

Safety

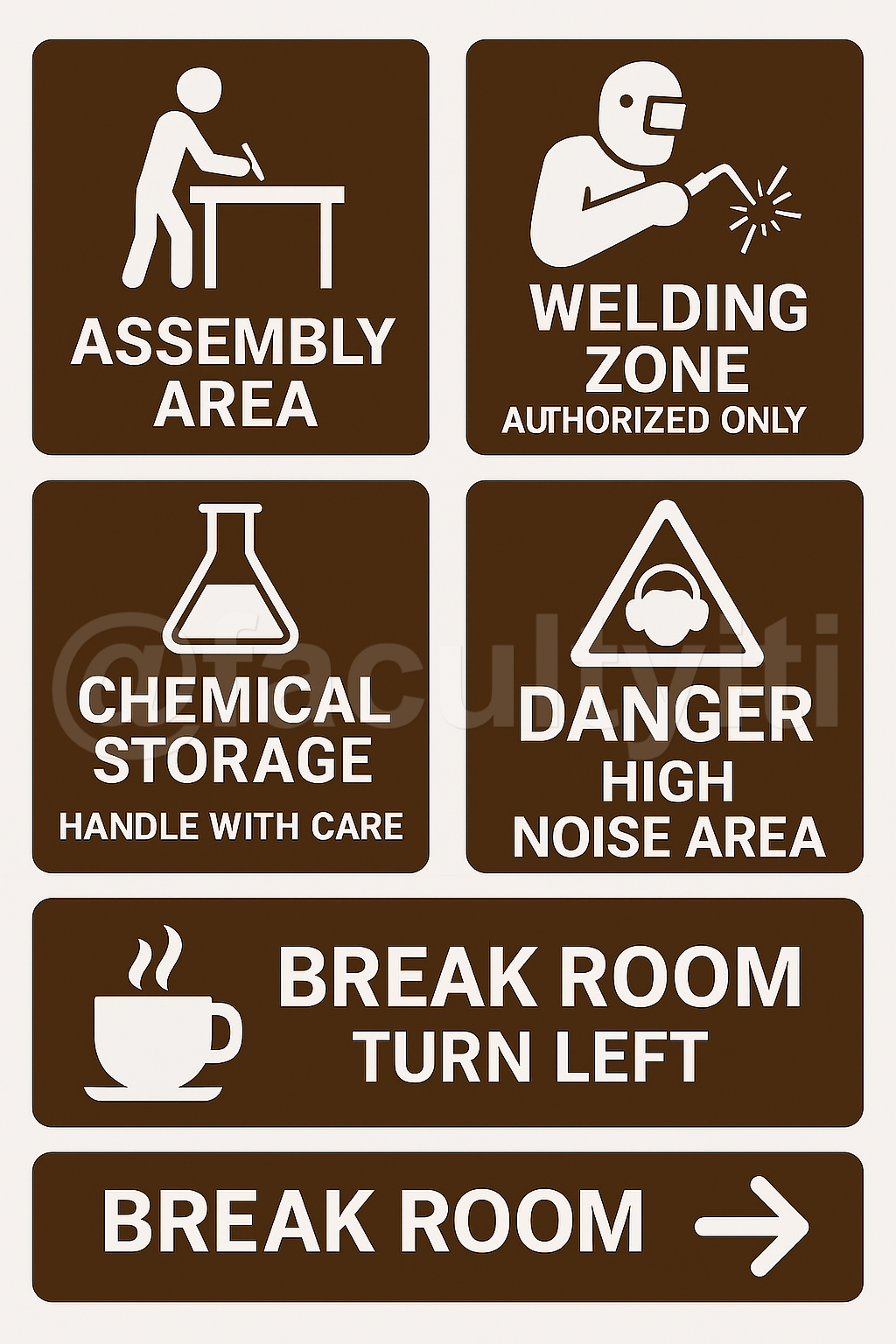

General Information Signs for Work Area and Navigation

Safety

Some General Information Signs for Safety and Emergency

Safety

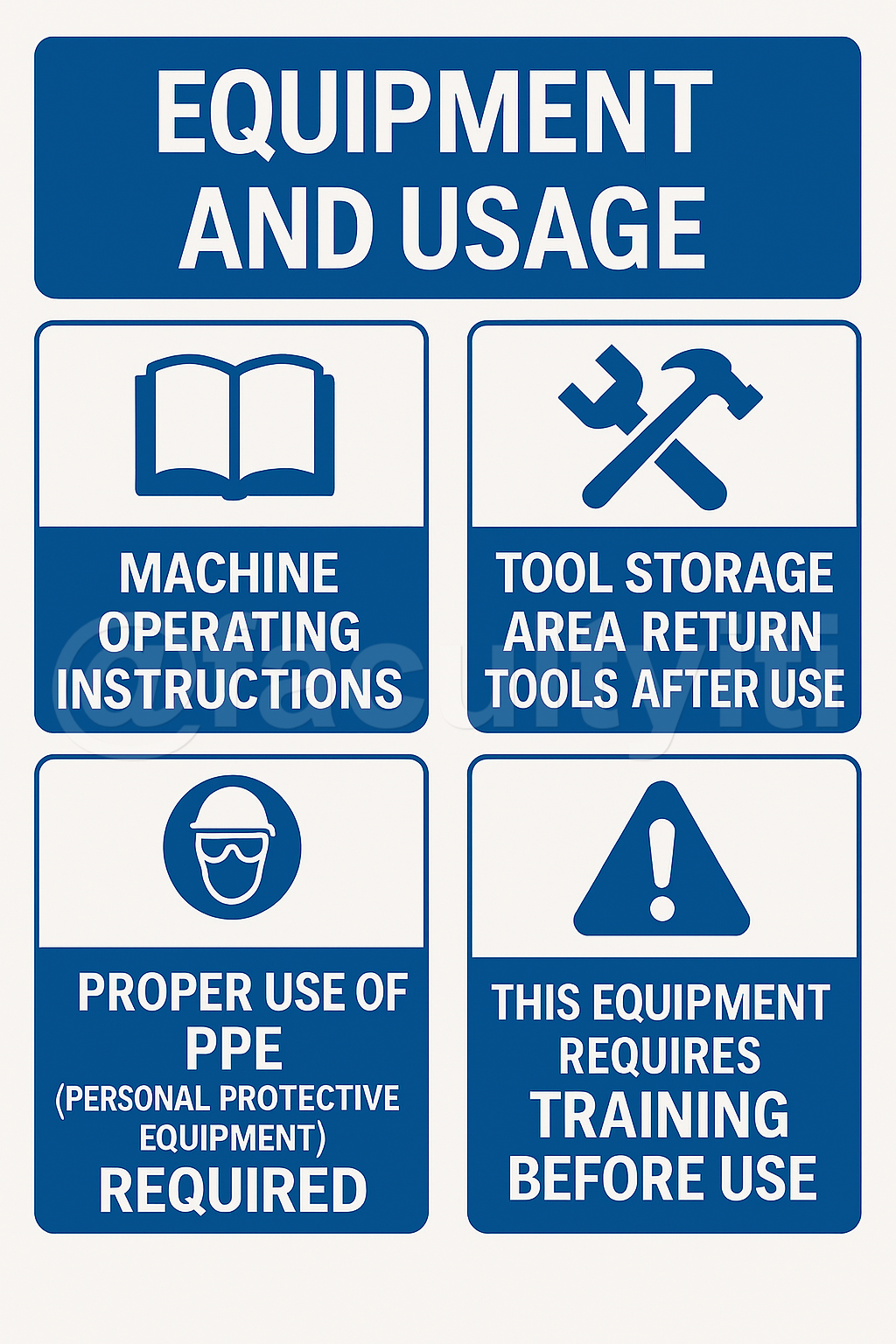

Some General Information Signs for Equipment and Usage

Safety

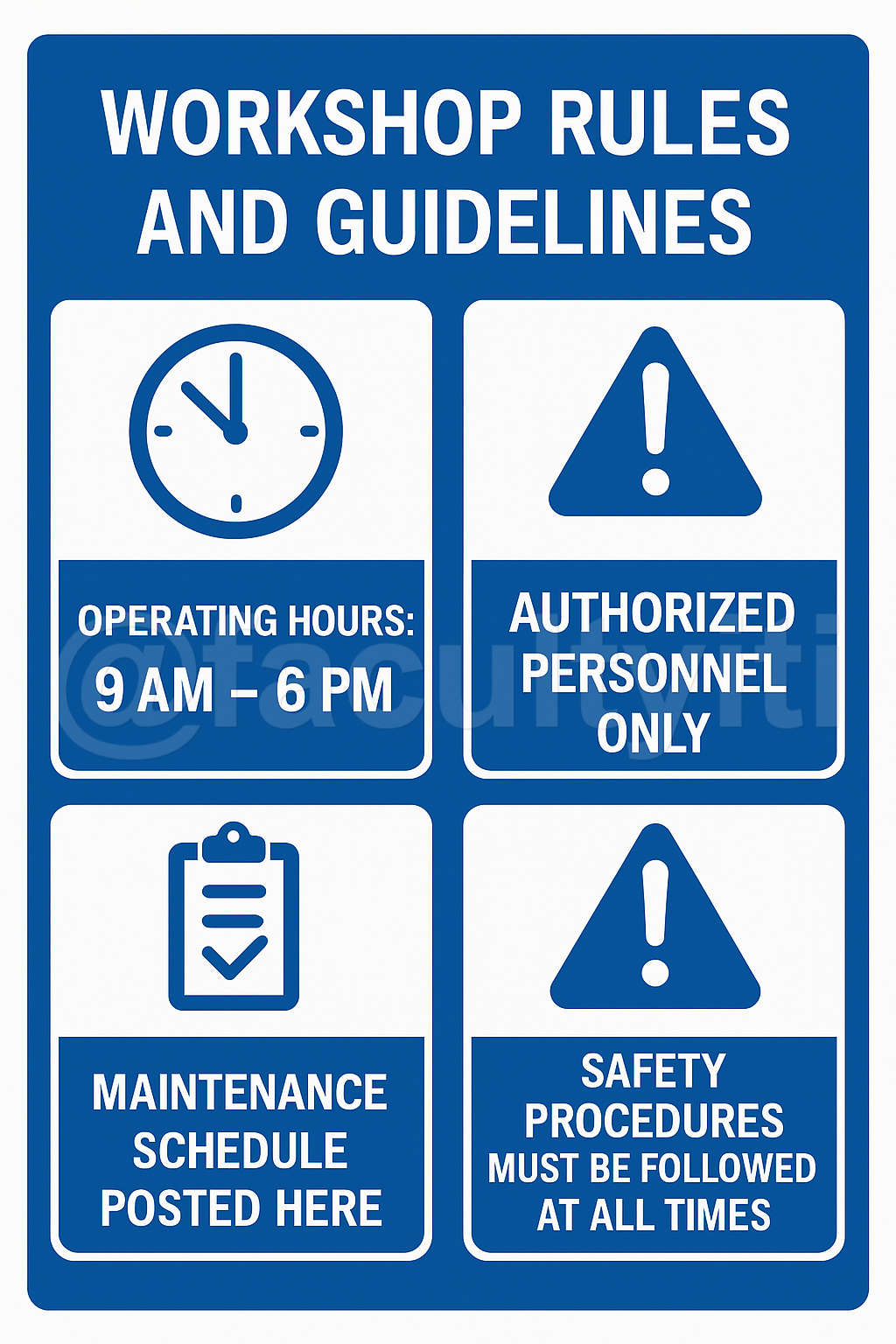

Some General Information Signs for Workshop Rules and Guidelines

Safety

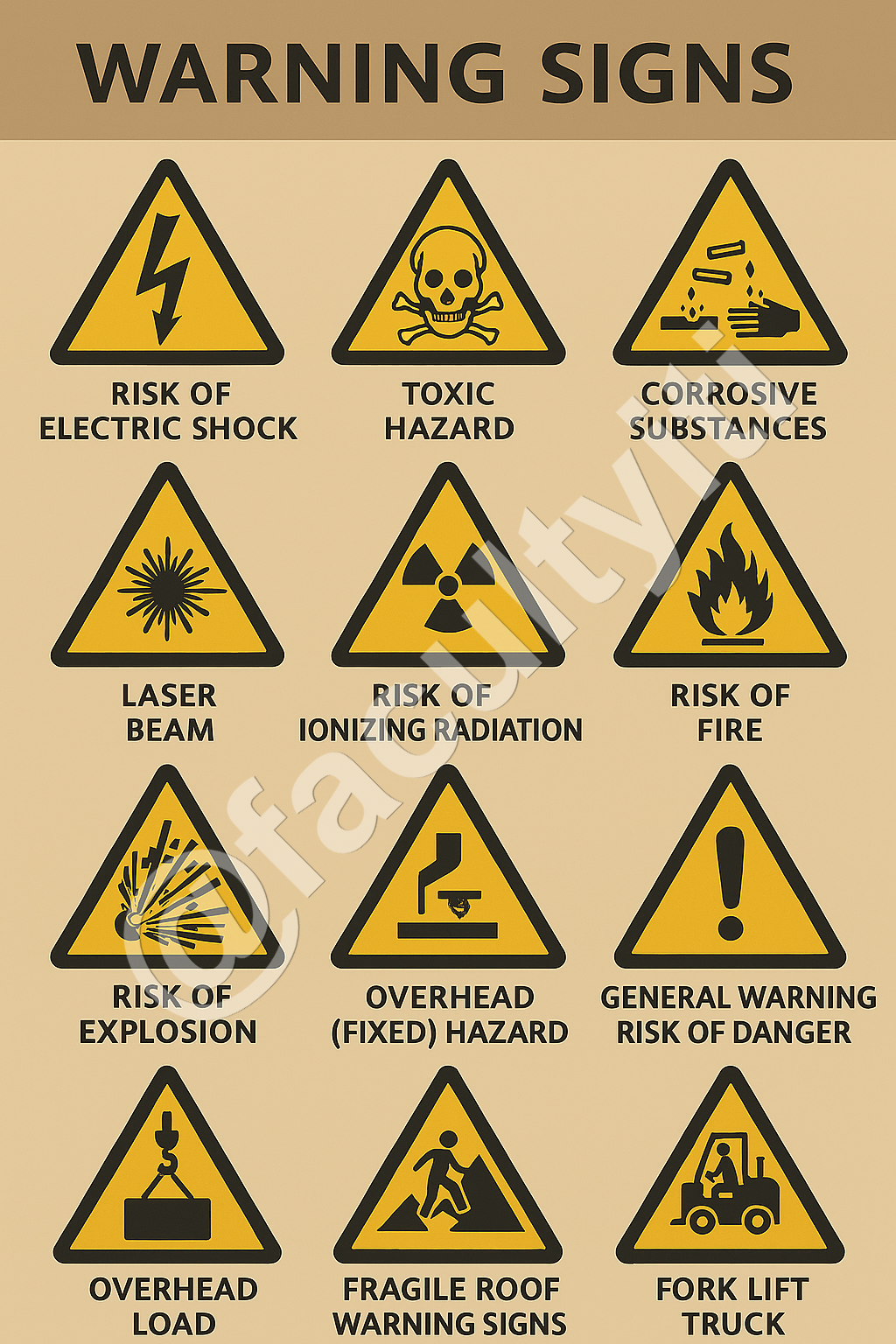

Warning Signs for Workshop Safety

Safety

Mandatory Signs for Workshop Safety

Safety

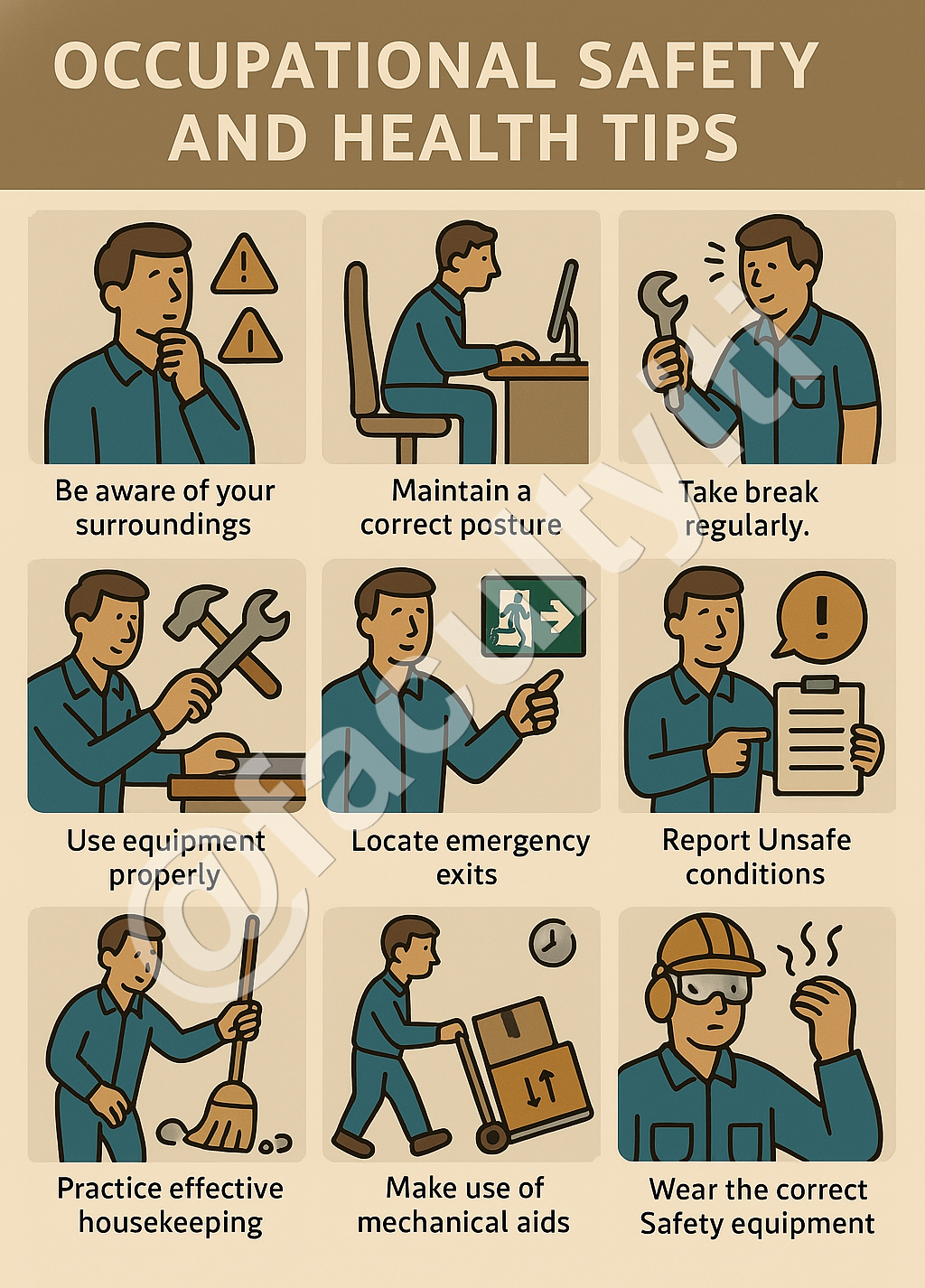

Occupational safety and health Tips:

1. Be aware of your surroundings.

2. Maintain a correct posture Take break regularly.

3. Use Equipment properly.

4. Locate Emergency Exits.

5. Report Unsafe conditions.

6. Practice Effective Housekeeping.

7. Make use of mechanical aids.

8. Wear the correct Safety equipment Reduce workplace stress.

Safety

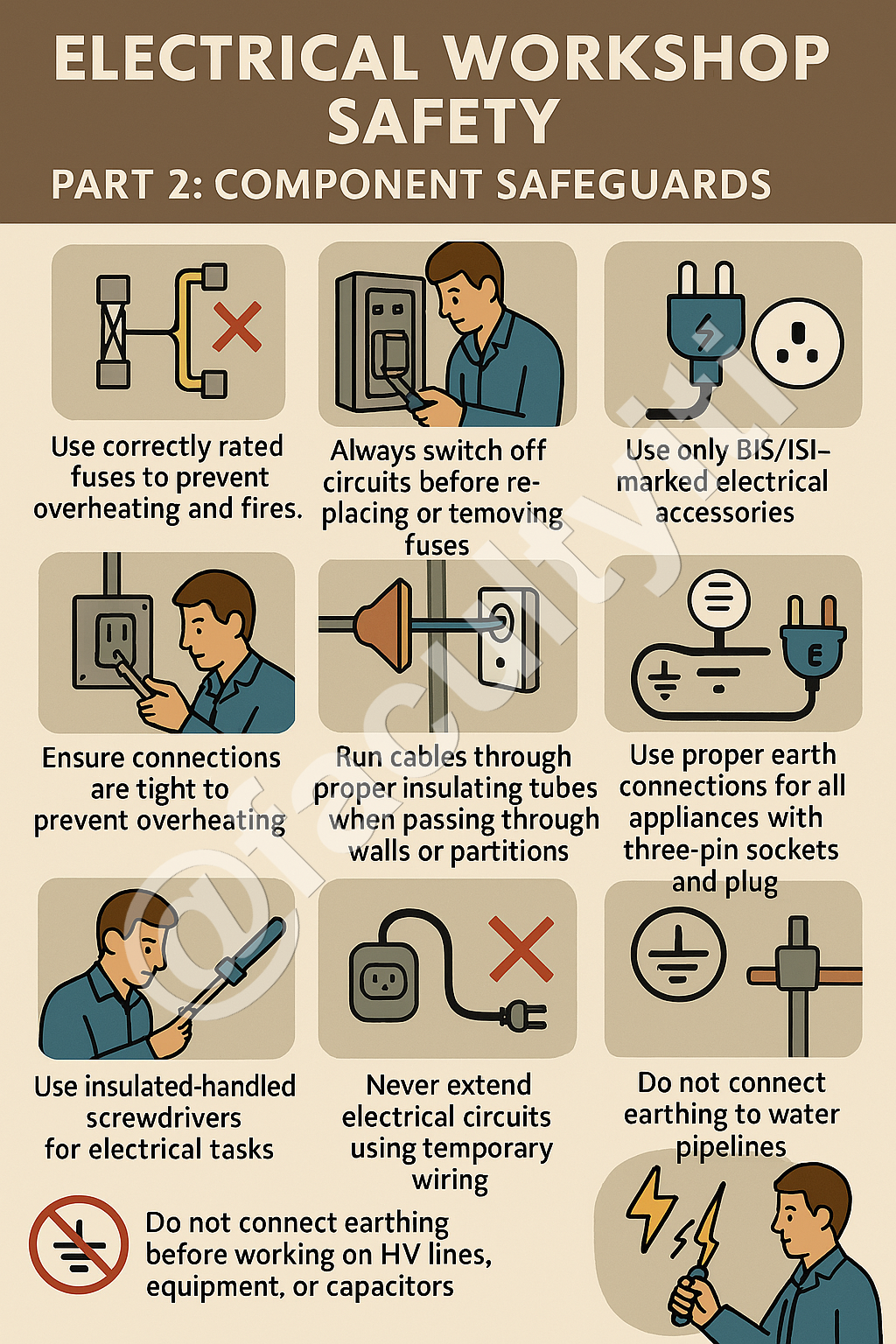

Electrical Workshop Safety

Part 2: Component Safeguards

1. Use correctly rated fuses to prevent overheating and fires.

2. Always switch off circuits before replacing or removing fuses.

3. Ensure connections are tight to prevent overheating.

4. Use only BIS/ISI-marked electrical accessories.

5. Run cables through proper insulating tubes when passing through walls or partitions.

6. Use proper earth connections for all electrical appliances with three-pin sockets and plugs.

7. Never extend electrical circuits using temporary wiring.

8. Do not connect earthing to water pipelines.

9. Discharge static voltage before working on HV lines, equipment, or capacitors.

10. Use insulated-handled screwdrivers for electrical tasks.

Safety

Electrical Workshop Safety

Part 3: Fire & Accident Prevention

1. Always use lamp guards for extension cords to avoid bulb breakage and fire risks.

2. Place hot soldering irons in stands—never on workbenches.

3. Display “Men on Line” signs when working on dead circuits.

4. Remove fuse grips for safety when working on circuits.

5. Ensure accessories (sockets, plugs, switches) are in good condition.

6. Stand on rubber mats when operating switch panels or control gears.

7. Identify proper machine operation before use.

Keep combustible materials away from electrical heat sources.

Safety

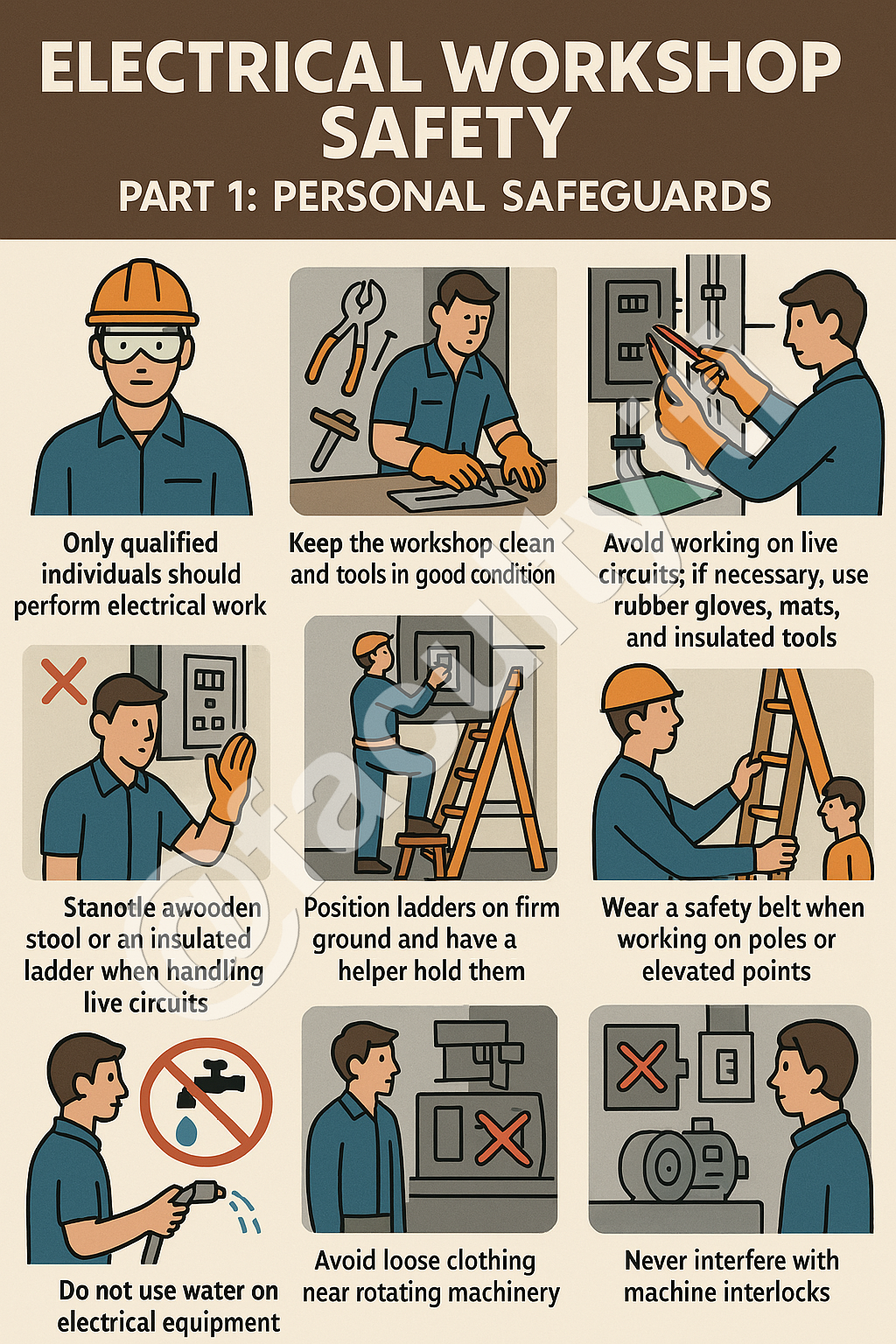

Electrical Workshop Safety

Part 1: Personal Safeguards

1. Only qualified individuals should perform electrical work.

2. Keep the workshop clean and tools in good condition.

3. Avoid working on live circuits; if necessary, use rubber gloves, mats, and insulated tools.

4. Never touch bare conductors.

5. Stand on a wooden stool or an insulated ladder when handling live circuits.

6. Position ladders on firm ground and have a helper hold them.

7. Wear a safety belt when working on poles or elevated points.

8. Avoid loose clothing near rotating machinery.

9. Never interfere with machine interlocks.

10. Do not use water on electrical equipment.